Therefore it is very important to obtain and maintain the original leakage rate of the furnace and ensure the working vacuum of the vacuum furnace to ensure the quality of vacuum heat treatment of parts.

Vacuum heat treatment furnace parts.

Ipsen s vacuum furnaces are designed to repeatedly deliver clean high quality parts.

Heat furnace to appropriate temperature profile to ensure properly heat treated parts.

Vacuum heat treatment furnace has a high degree of automation because the operation of heating and cooling of metal workpieces requires dozens or even dozens of actions to complete.

With standard and custom products available we can build the right furnace for your heat treating needs.

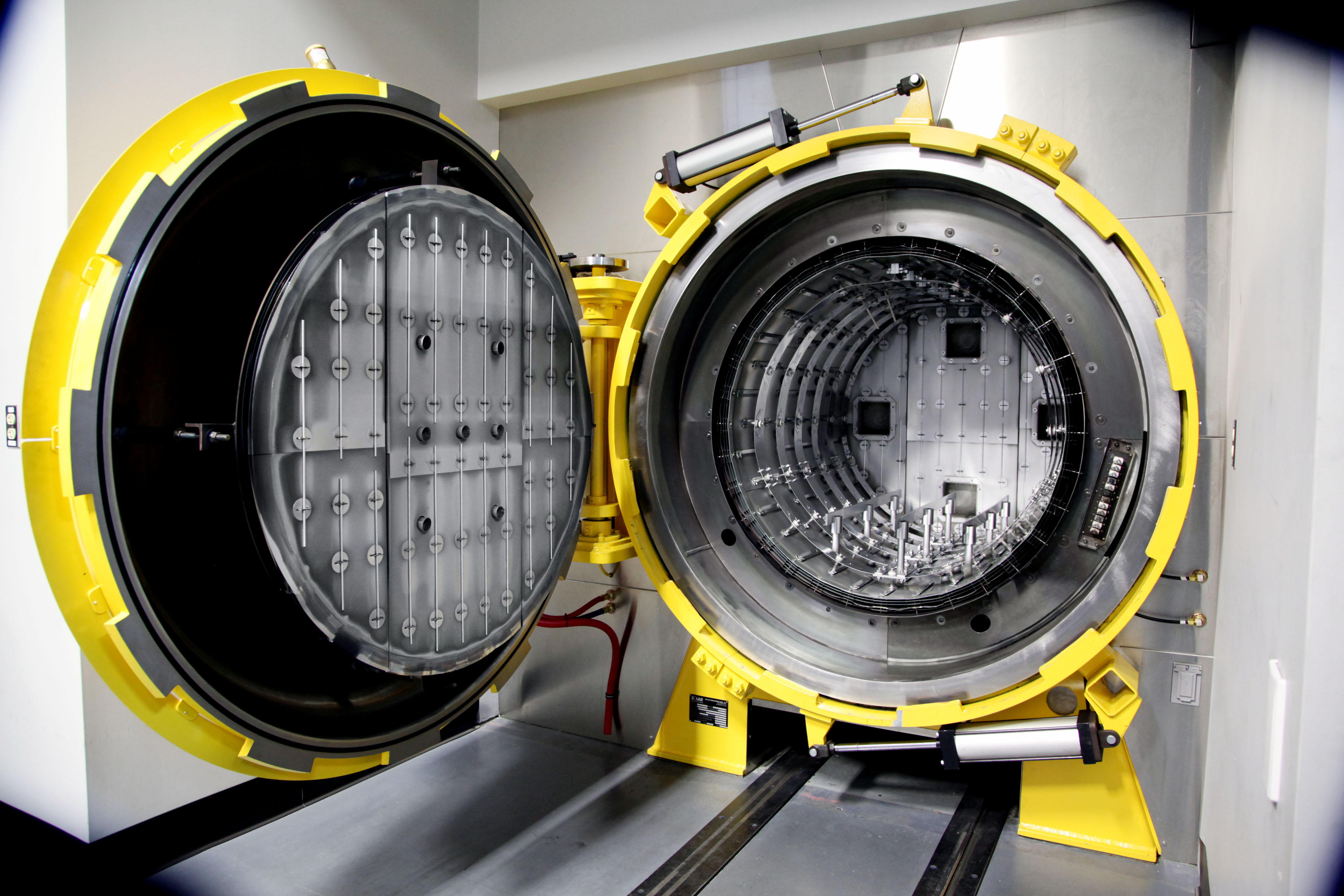

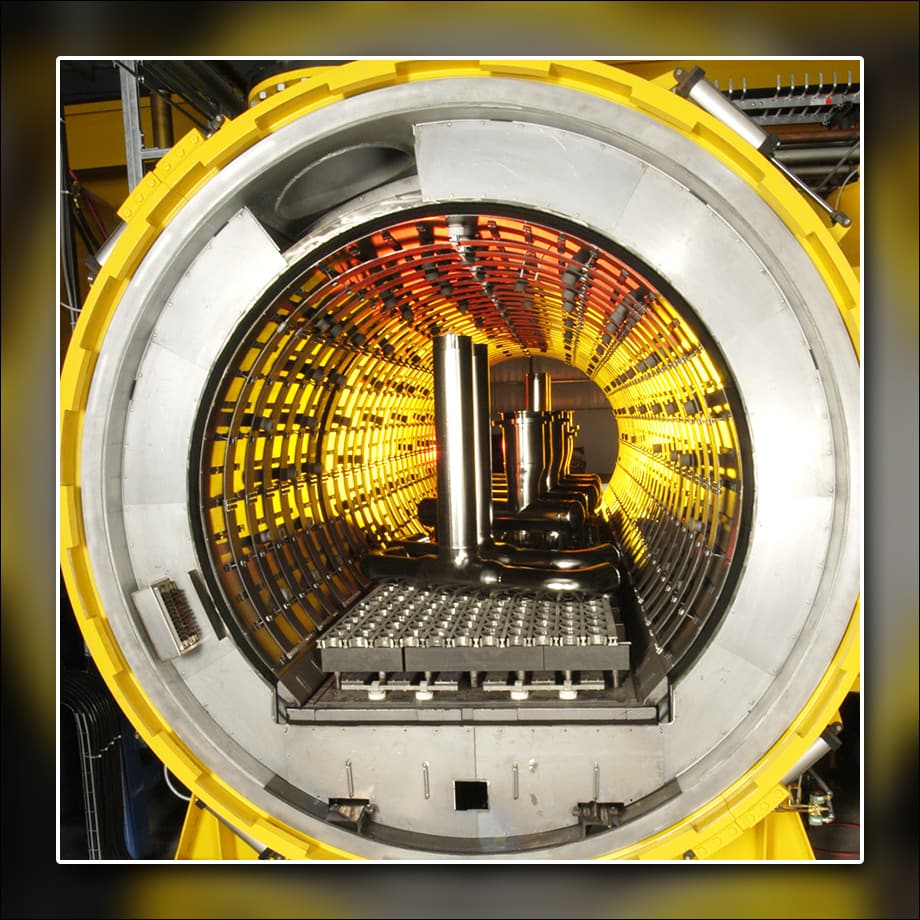

Vacuum heat treatment of metal parts is carried out in a closed vacuum furnace.

For gas cooled vacuum furnace nitrogen gas storage tank should be provided.

Three of the great benefits of vacuum heat treatment are.

Guidelines for selecting vacuum furnaces vacuum furnaces for creation of new values.

Each of our modern vacuum furnaces have automatic micro processor controls to insure that your parts are treated to the exact specified design requirements.

Benefits of vacuum heat treating.

Vacuum heat treating is clean easy to control and safe.

These are typically placed atop carrier grids.

The results are clean shiny parts with minimal distortion and which require comparatively little post treatment finishing and cleaning.

How parts are loaded is very much a function of the geometry of the part as well as the style of the furnace being used.

Oxygen is removed from the chamber and replaced with.

Essentially parts are positioned in a special chamber.

Vacuum furnace is composed of furnace body vacuum unit hydraulic system control system cooling system and other parts.

The most common arrangement used in horizontal vacuum furnaces is rectangular baskets designed for stacking or nesting fig 1 below.

In order to prevent water shutdown or insufficient water pressure high altitude water tank should be provided to prevent seals and electrodes from burning out or ablating due to water shutdown.

This will often liberate chrome from the parts and fixtures 4 the hot zone absorbed water vapor refer to 1 for why 5 water jacket leaks heat exchanger leaks traces of water etc.

3 the furnace was run at high temperatures while in a very deep vacuum.

.png)